Protective Device Coordination

What is Circuit Breaker Coordination?

Electrical systems commonly use fuses and circuit breakers to protect their electrical equipment.

In the event that a failure occurs, it would be desirable that a short circuit would affect only the portion of the electrical system where the failure occurs, instead of the entire system.

A circuit breaker coordination study is used to analyze the tripping times for the series of over current devices being compared, generally from the source through the largest branch circuit device.

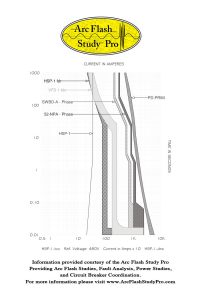

The curves are a logarithmically graphical representation of the performance characteristics of the devices at a base voltage of 480 volts.

The methodology is to optimize the selectivity of the devices. Selectivity is the isolation of a faulted circuit to the point of fault without disturbing any of the other protective devices in the system.

A properly coordinated system has each of its protective devices adjusted as to minimize the negative impact of equipment failures.

Note: A Protective Device Coordination Study may also be referred to as a Circuit Breaker Coordination Study, Time Current Coordination, or as Electrical Power System Protection.

|

| Sample of a Circuit Breaker HSP-1 Analysis |

Do I need a Protective Device Coordination Study?

Most electrical power distribution systems are not planned with protective device coordination in mind, and can fail miserably in the proper coordination of the protective devices.

Equipment failures within the system for something as small as a single motor can easily result in having to shut down your entire facility!

A protective device coordination study can help prevent this from happening. Ask yourself:

- Have you recently had electrical equipment failures that caused extensive and expensive downtime to your company’s operations?

- Are you beginning or in the preliminary design stages of building a facility worth over $1 million that will house your employees?

- Do you already have installed or plan on installing uninterruptible power supplies (UPS), emergency generators, or static transfer switches in your electrical system?

- Would the resulting downtime cost exceed $3,000/hour if you had an electrical failure in your facility?

- Do you have critical equipment or inventory that could be damaged if a long-term power outage occurred?

What benefits would I receive from having a Study performed?

A Protective Device Coordination Study will show you the probable and possible values of fault currents within the system and show you impact short circuits and failures would have on your fuses, circuit breakers, and your facility’s operation.

More specifically:

- Increased Facility Reliability

(Estimated downtime alone can cost as high as $200,000 per hour!*)

(Click here to see estimations!) - Increased Equipment Protection

- Increased Operating Efficiency

- Will aid in current operations and help prevent downtime

- Prevent damage by identifying underrated equipment

- Prevent damage by identifying overloaded equipment